Asahi Seiko can process a wide variety of machines using machining tools, such as square/round material, materials such as iron, aluminum material, stainless steel, brass, SCM and SK which are difficult to process.

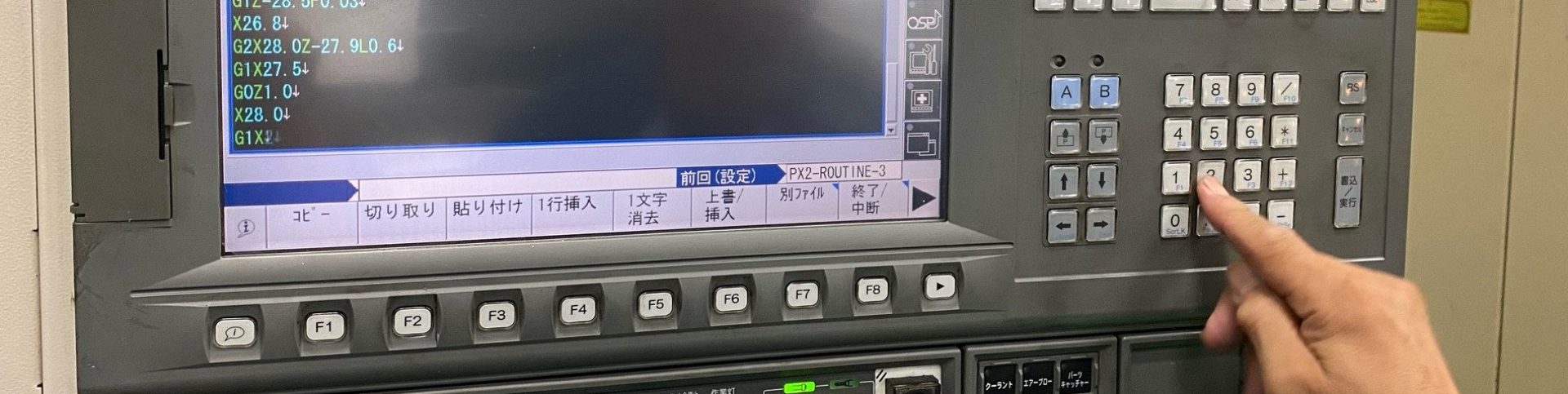

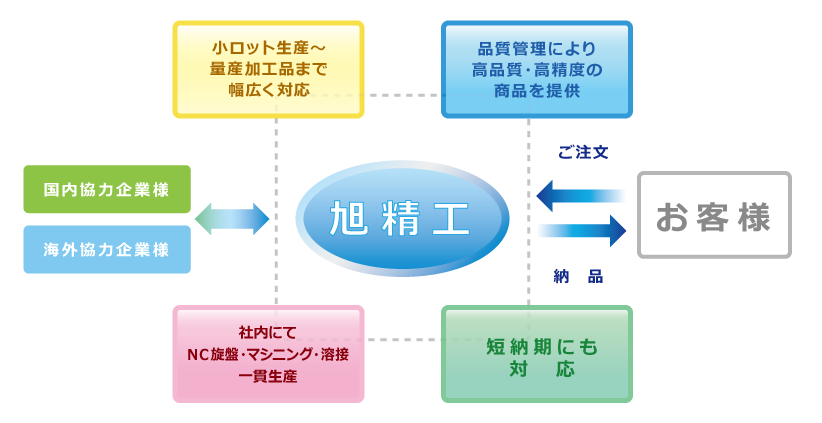

Our strength is that we can reduce costs by consistently doing NC lathes, machining centers and welding in-house.

All items that can be handled by owned equipment are produced internally.

In addition, other parts can also be processed from material procurement to surface treatment by cooperation with cooperating companies, and finished products can be provided to customers.

We also realize low cost production of mass-produced products and support parts procurement through cooperating companies abroad.

From prototype processing products to single product parts processing, or from small lot order to mass production order, we will respond to customer’s needs widely including short-term delivery.

In terms of quality control, we have various measuring instruments, and we manage it for all processed products inside and outside the company.

Asahi Seiko will contribute to people and society through “manufacturing” that has been committed to satisfying customers.

Asahi Seiko’s Technology

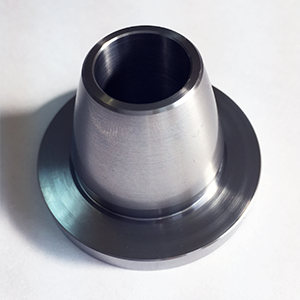

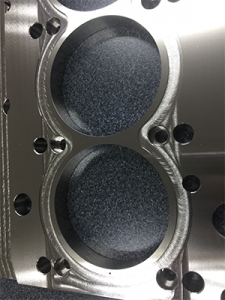

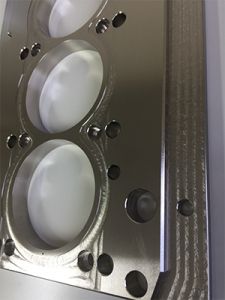

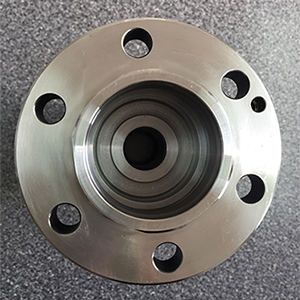

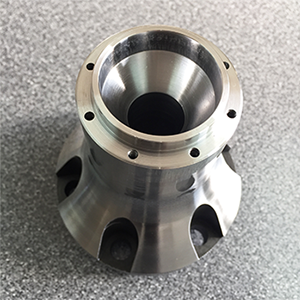

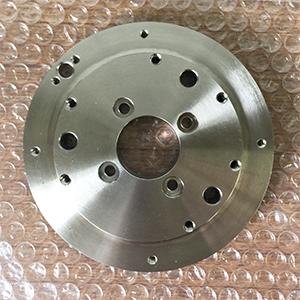

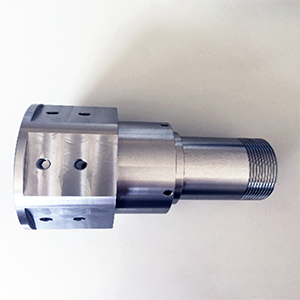

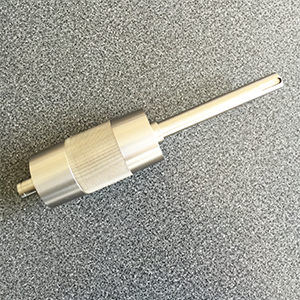

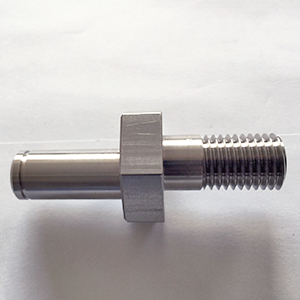

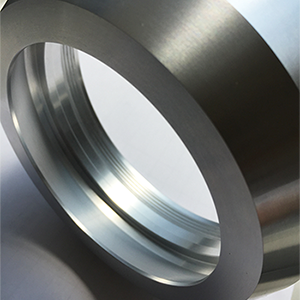

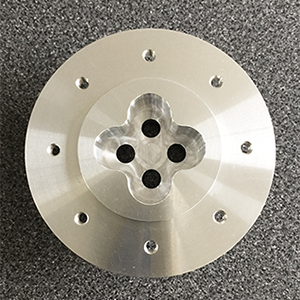

Here are parts of Asahi Seiko’s items.

Iron

| SS400 |      |

| S45C |  |

|

S50C |

|

| SCM435 |   |

Stainless Steel

| SUS303 |  |

| SUS304 |      |

Alminium

| A2017 |     |

Brass

| Brass |  |